High-performance battery electrodes are a critical component of lithium-ion cells. The coated electrode materials for cathodes and anodes must meet high requirements for energy efficiency, storage density, and safety.

Good coating quality on an aluminum cathode or copper anode is critical to avoid battery failures. Achieving this can be challenging, as production operates at high speed and the defects are small.

The production goal is to achieve a particularly smooth and closed coating as well as 100%-layer detection of both coating surfaces, so precise quality inspection and dimensional verification is required.

AMETEK Surface Vision delivers trusted highly accurate solutions for battery electrode coating processes, maintaining line speeds and rapidly detecting defects including agglomerate, coating spots, particles, missing coating, wrinkles, scratches, holes, edge cracks, and dents.

DOWNLOADABLE DATASHEET

Surface Inspection of Battery Electrode Material

Download EN >

Surface Inspection of Battery Electrode Material

Download EN >

EXAMPLE DEFECT TYPES

EXAMPLE DEFECT TYPES

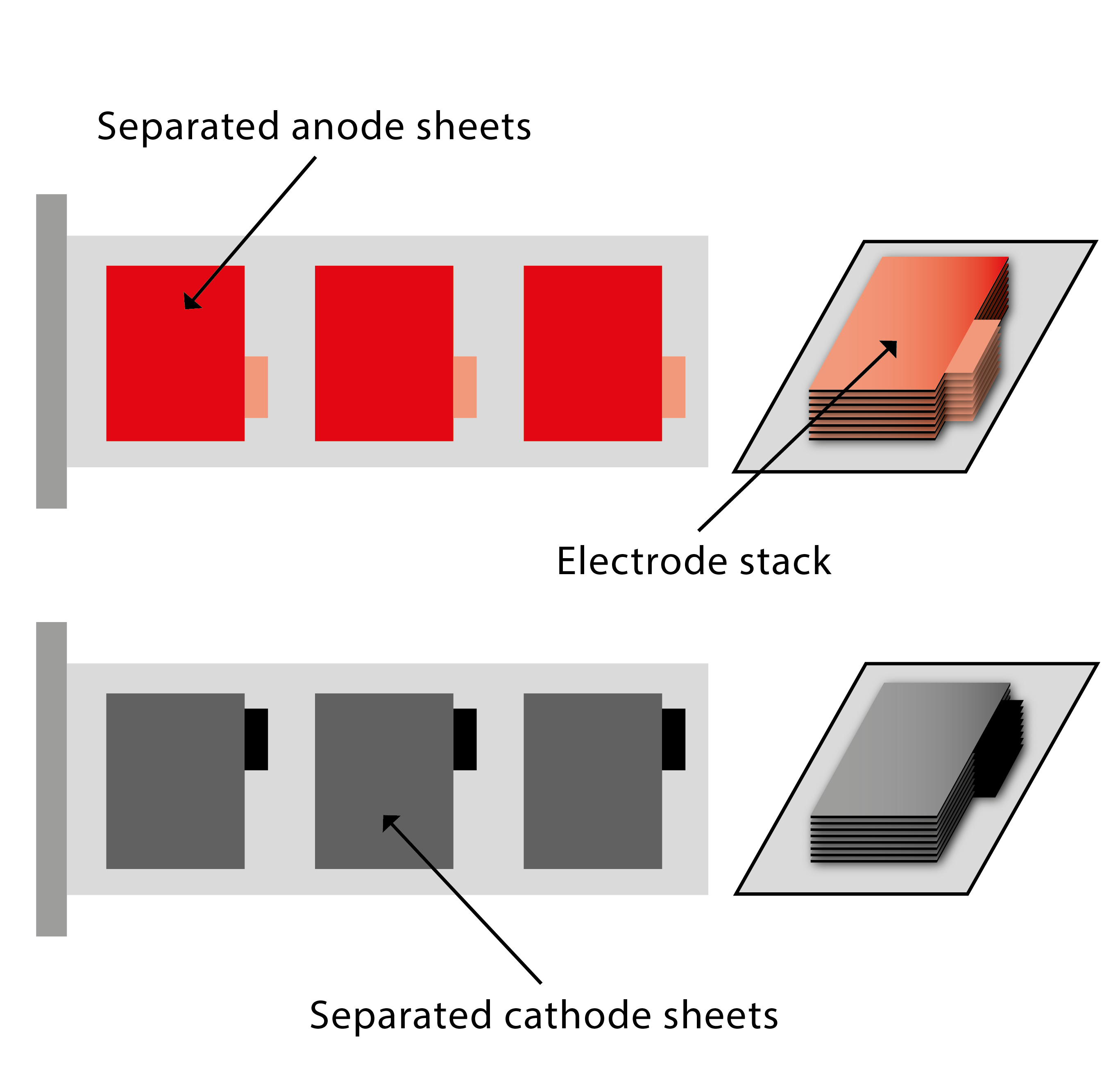

BATTERY ELECTRODE SINGLE SHEET INSPECTION

BATTERY ELECTRODE SINGLE SHEET INSPECTION