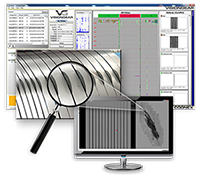

SmartView® Slit Inspection reliably detects, classifies, tracks and reports surface defects on both sides of multiple coil slits, even at line speeds greater than 1,000 feet per minute.

The system provides complete, high-resolution surface inspection at full line speeds, delivering instant feedback. This allows the operator to act swiftly to limit waste, increase yields and safeguard product quality.

Providing an automatic quality inspection solution that easily surpasses manual methods, SmartView

® Slit Inspection combines patented inspection and classification technology with extensive engineering knowledge for cutting-edge defect detection and reporting.

Widely used in the flat-rolled metals processing industry, SmartView Slit Inspection is an industrial-grade surface inspection solution for slitting processes in

metals industries.

CONSISTENT DATA RECORDS

SmartView Slit Inspection creates accurate mapping and precise reporting for each coil or mult. These records can be used in supply chain management or customer quality assurance, and archived for claim resolution.

ELIMINATES RECOILING NEEDS

By accurately scanning and reporting both sides of the strip, with instant operator notification, SmartView Slit Inspection ensures there is no need to recoil to investigate suspected quality issues. This speeds up the process, increasing production yield with no loss of quality.

FASTER LINE SPEEDS

Our patented inspection and classification technology combines with expert equipment configuration to provide reliable, automatic 24-hour inspection without having to slow slitter lines. Production capacity increases while the cost of inspection is reduced.

SmartView Slit Inspection is AMETEK Surface Vision’s high-speed, high-resolution quality inspection solution for flat material slitting operations – Find out more by contacting us.

BROCHURE

METALS SURFACE INSPECTION

METALS SURFACE INSPECTION

Metal manufacturers face ever-increasing demands to improve quality, increase productivity and create certified defect free products, especially from end-user markets such as the automotive and aerospace industries. This makes a flexible, customizable surface inspection solution essential when optimizing quality and yield.

View the brochure as pdf>

View the brochure as e-mag>

CASE STUDY

Metal insights forge greater ROI for copper manufacturer

Metal insights forge greater ROI for copper manufacturer

Customer: Sofia Med -

www.sofiamed.bg

Industry: Copper

Products(s): SmartView

®

View the case study >