There are a variety of solid-state battery concepts available, each based on different classes of solid electrolytes. Each technology faces challenges including the scale-up of material production, component compatibility and production issues.

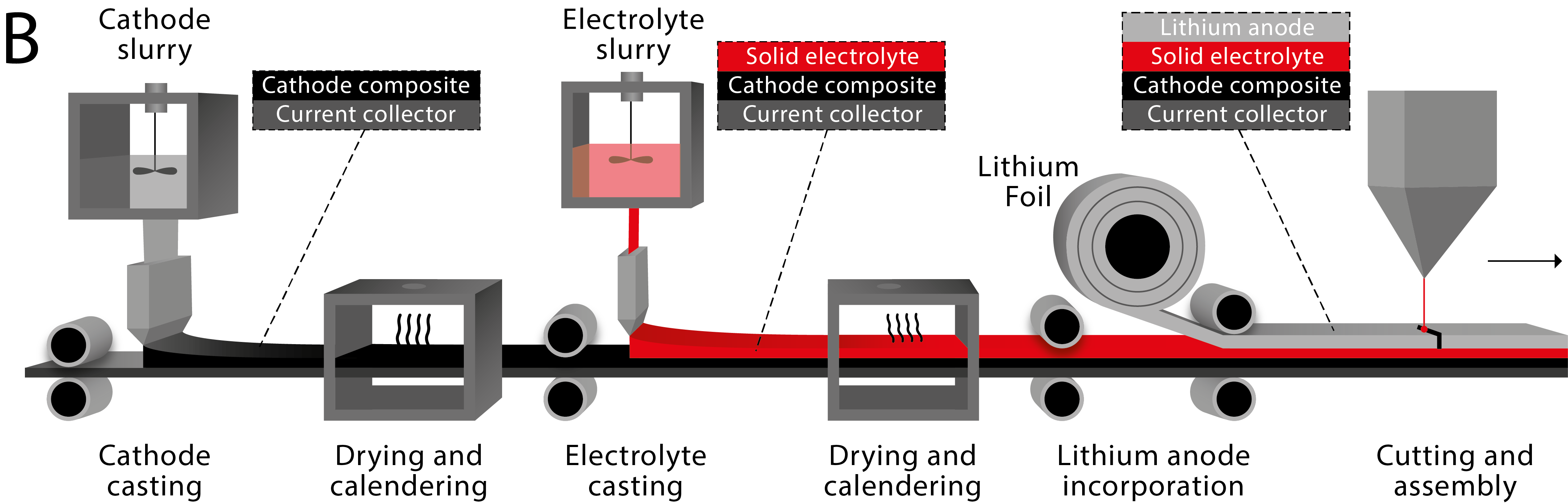

Unlike established lithium-ion battery designs, solid-state batteries use a solid electrolyte rather than a liquid one. The main components of the battery cell are the anode and cathode active materials and the solid electrolytes.

Surface inspection systems can be installed across the production process to inspect cathode and anode composition, the electrolyte, and the current collector. Typical defects include lamination errors, blisters, holes, wrinkles, particles, and coating defects.

AMETEK Surface Vision delivers trusted highly accurate solutions for solid-state battery production processes, rapidly detecting defects on a variety of materials and components.

Typical Inspection Location

Typical Defects

Typical Defects

DOWNLOADABLE DATASHEET

Inspection Of Solid State Batteries

Download EN >

Inspection Of Solid State Batteries

Download EN >