REAL-TIME ELECTRODE INSPECTION & TRACEABILITY

In the rapidly evolving and highly competitive electric vehicle (EV) industry, battery cell quality and manufacturing efficiency are paramount.

To ensure safe and primary electrode products, AMETEK® Surface Vision implements high-performing automated online surface inspection systems throughout the entire production process allowing for the identification of surface defects at each step.

Download EN >

GLASS FIBRE PRODUCTION

To inspect glass fiber processes, AMETEK Surface Vision uses its SmartView web inspection and SmartAdvisor® web monitoring products together in a unified platform called SmartSync.

This total vision integration combines the power of advanced SmartView classification with the flexible, multi-position camera technology of SmartAdvisor.

As a result, the operator can rapidly determine the root cause of any defects and take the necessary corrective action.

Download EN >

BATTERY SEPARATORS AND ELECTRODE MATERIAL

With the growing global movement towards renewable energy, and the need to find alternative power sources to fossil fuels, electric-powered vehicles are increasingly in demand. This, in turn, has led to a rapidly rising demand for high-quality electric battery cells to power these vehicles. To ensure a high-grade battery, defect-free separators and high-quality electrodes are required.

Download EN >

THE ROLE OF THE SMARTVIEW® ADVANCED WINDER ADVISOR IN NONWOVENS MANUFACTURE

Advanced Winder Advisor (AWA) allows winders to be accurately and repeatedly stopped to remove defects while also increasing winder efficiency. AWA is designed to seamlessly integrate with SmartView inspection systems on the nonwoven production line to create a closed-loop quality control solution.

Download EN >

SURFACE INSPECTION OF MOBILE DEVICES AND DISPLAYS

Modern touchscreens and display panels, used for applications ranging from mobile phones and tablets to OLED and LCD televisions, are expected to meet the highest standards of quality and performance. The materials used in touch panels and screens must meet strict criteria to ensure they provide a clear, high-quality display, withstand frequent use, and allow accurate touchscreen operation.

Download EN >

Download ZH >

BENEFITS OF COLOR CAMERA INSPECTION SYSTEMS FOR PULP CONTAMINANT DETECTION

Color cameras have previously had a limited presence in automated surface inspection for the pulp industry. Existing installations have proven that inspection systems using monochromatic cameras are fully capable of detecting contamination in the pulp. However, there are some limitations to these cameras when it comes to distinguishing certain contaminants – for example, dark spots and color plastic.

Download EN >

Download ZH >

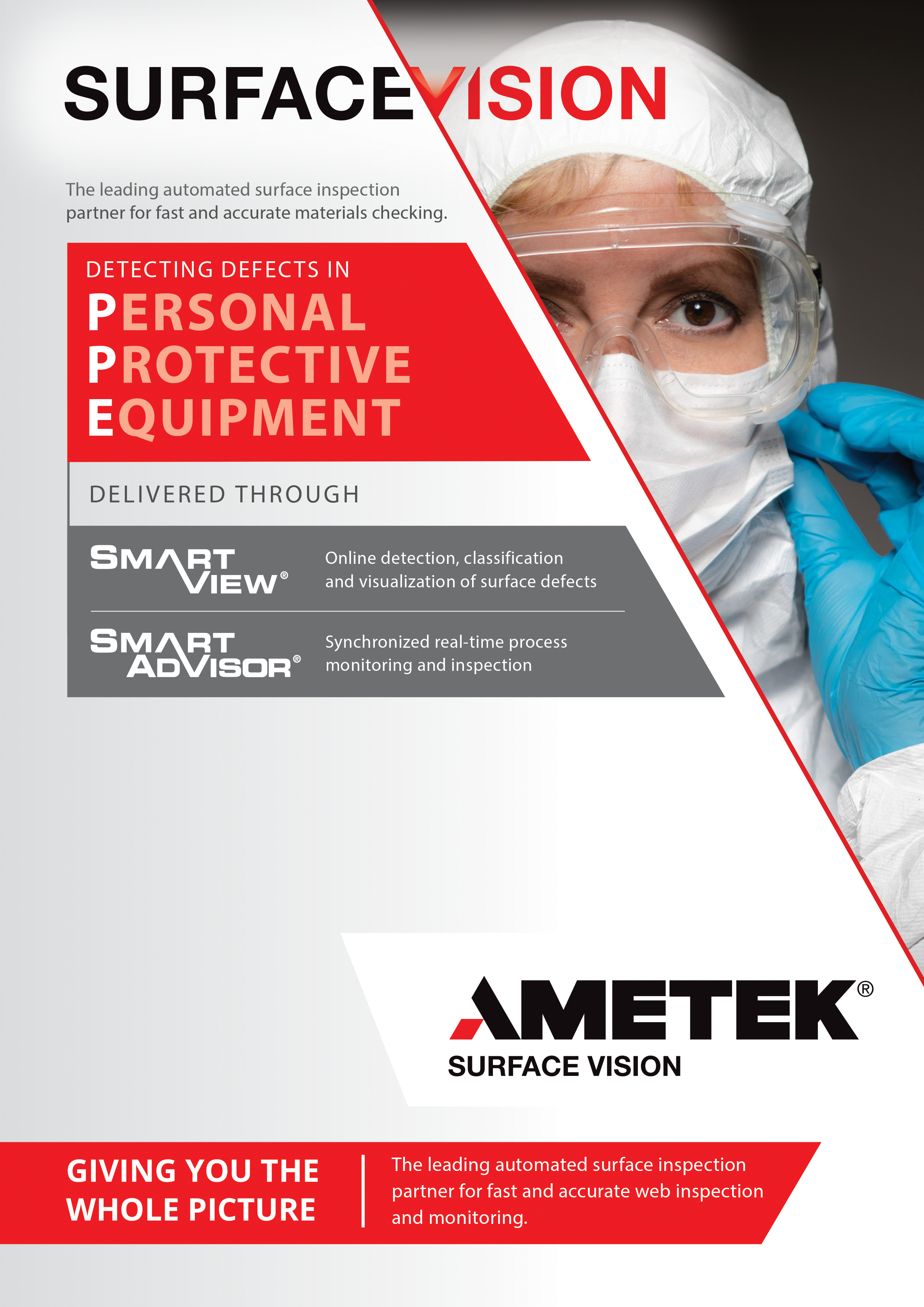

DETECTING DEFECTS IN PERSONAL PROTECTIVE EQUIPMENT

Personal Protective Equipment (PPE) is essential to a range of workplace applications, particularly Healthcare. Many of these PPE items are partly or wholly manufactured from nonwoven materials. Since nonwovens protect against airborne particles while providing air permeability, this quality must be safeguarded in order to produce effective PPE that is safe to use.

Download EN >

Download ZH >

AUTOMOBILE INDUSTRY COMPONENT INSPECTION

Modern automobiles are assembled from hundreds of components, each made from metal, plastics, glass or nonwoven materials. The safety, quality, and proper operation of the vehicle depends upon the standard to which these components are produced. Automobile part manufacturers rely on automated surface inspection solutions to ensure quality and increase productivity, delivering defect-free products.

Download EN >

Download ZH >

SURFACE INSPECTION SOLUTIONS FOR METALLIZED PAPER

SURFACE INSPECTION SOLUTIONS FOR METALLIZED PAPER

Metallized paper is produced by coating paper with a thin layer of vaporized aluminum, giving it a finish that adds decorative and protective properties to the product. It is primarily used in packaging, for example in labels, inner liners, gift wrap and other consumer product applications.

The sustainability of paper, and the superior appearance of a metallic surface, promotes this application in the packaging market.

Download EN >

Download ZH >

ALUMINUM COLD MILL

ALUMINUM COLD MILL

Cold rolling is an important part of the manufacturing process for thin aluminum strip and sheet. Effective quality control at this stage, by monitoring dents, scratches and other surface defects, can protect from claims and reduce costs throughout the production process.

Download EN >

Download ZH >