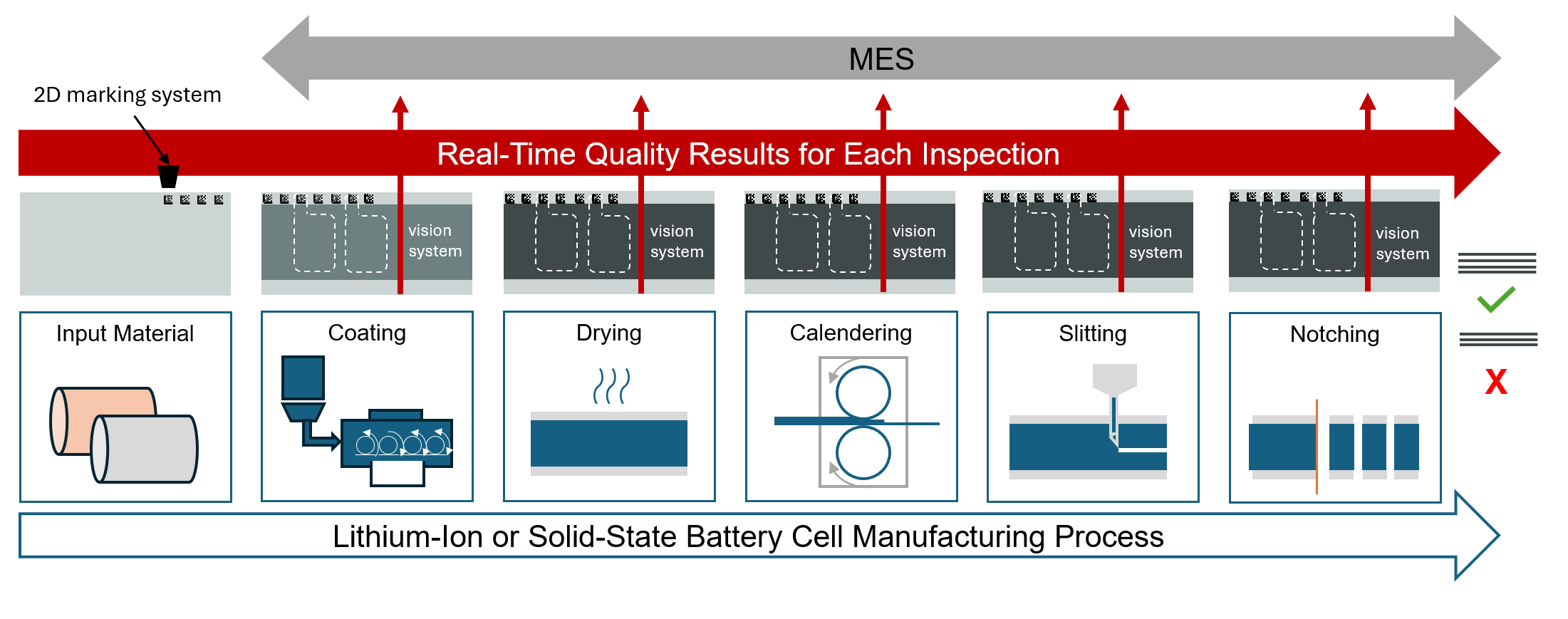

Achieving comprehensive traceability is vital across various process steps in advanced battery manufacturing, including electrodes, separators, solid-state batteries, and fuel cells. Fiducial markers allow for each component to be uniquely identified and tracked throughout the production process.

AMETEK Surface Vision implement high-performing automated online surface inspection systems that integrate real-time defect detection with fiducial marker tracking. This combination enables precise monitoring of quality across all battery components, ensuring that defects are detected and logged at each stage.

PRODUCT TRACEABILITY WITH FIDUCIAL MARKERS

Curious to learn how this level of traceability can benefit your production line? Check out our latest application note to explore how our advanced inspection systems bring full traceability to life, enhancing both quality and operational efficiency.

Contact us and talk to our experts about your individual application.

Downloadable Application Note

REAL-TIME ELECTRODE INSPECTION & TRACEABILITY

Download EN >

REAL-TIME ELECTRODE INSPECTION & TRACEABILITY

Download EN >