AMETEK Surface Vision’s powerful SmartView Inspection System reduces the need for manual intervention, and adapts to the huge variety of separator membrane types in batteries.

The industry-leading surface inspection solution, SmartView is trusted worldwide to detect, identify and visualize surface defects in real time. Merging state-of-the-art software and hardware into an advanced surface inspection platform, SmartView provides total vision integration for high-speed defect detection, monitoring, and reporting. It delivers robust features, flexible operation, and proven, high-quality results.

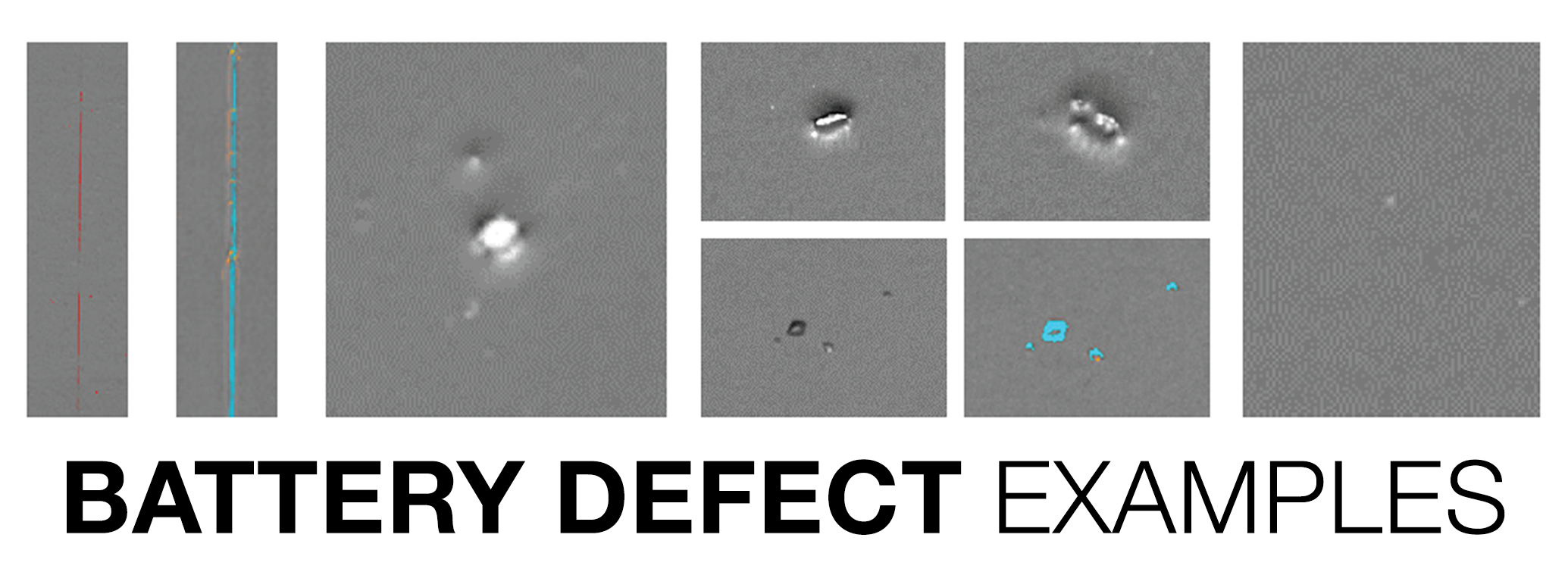

Installed on the coating and slitting processes in most applications, SmartView’s high-speed inspection system delivers high-resolution image acquisition of the following defect types:

- Contamination

- Strips

- Relief material

- Cutaways

- Coating defects

- Insects

- Pinholes

- Folds

- Foreign particles

- Pollution.

SmartView technology is quick and easy to install and designed with a user-friendly interface to support customer needs. Real-time notification technology allows operators to add control labeling systems to high light defect positions which optimize yield management and increase throughput.

Using the inspection and monitoring solution provided by AMETEK Surface Vision, battery cell manufacturers can be assured of adaptable defect detection that supports quality and reduces the need for manual intervention.