AMETEK Surface Vision’s modular solution, using its SmartView® detection technology, is the industry-leading surface inspection solution, trusted worldwide to detect, identify, and visualize surface defects in real time for a range of materials.

Key Features:

Precision Imaging

To distinguish between non-quality-related optical effects and genuine defects in battery production, manufacturers need a highly sophisticated optical set-up. Our advanced imaging technology captures high-resolution images, allowing for a meticulous examination of the battery surface.

Real-time Analysis

With real-time data processing capabilities, our technology identifies defects instantly, enabling swift corrective action and minimizing production delays. Established machine learning algorithms combined with a powerful detection algorithm and a multi-step classifier. Smart View provides a comprehensive overview of the battery's condition, identifying imperfections such as scratches, dents, or other irregularities that may compromise performance.

Versatility

Our surface inspection technology is adaptable to various battery types, accommodating the diverse specifications of electric vehicles on the market. A high-speed inspection system merging state-of-the-art software and hardware into an advanced surface inspection platform reduces the need for manual intervention and can adapt to the huge variety of battery separator membrane types.

Enhanced Safety

By detecting and addressing potential surface irregularities early in the manufacturing process, our technology contributes to the overall safety and reliability of EV batteries.

SmartView can be supported by the versatile, easy-to-use

SmartAdvisor vision system, designed to maximize machine efficiency and yield rates. This provides high-speed, multi-dimensional video monitoring and process analysis, helping to optimize processes, find defects, and detect process upsets.

Together, these systems provide rapid inspection of anode and cathode coatings, thin-film separators, solid-state battery components, and fuel cell components, assuring battery cell manufacturers of adaptable defect detection that supports quality and reduces the need for manual intervention.

Explore the possibilities of our

surface inspection technology and how it can elevate your EV battery manufacturing processes. Schedule a demonstration or get in touch with our team to discuss how our solution can be tailored to meet your specific needs.

In an era where innovation drives progress, our surface inspection technology stands at the forefront of ensuring the reliability, safety, and efficiency of electric vehicle batteries. Together, let's pave the way for a sustainable and electrifying future.

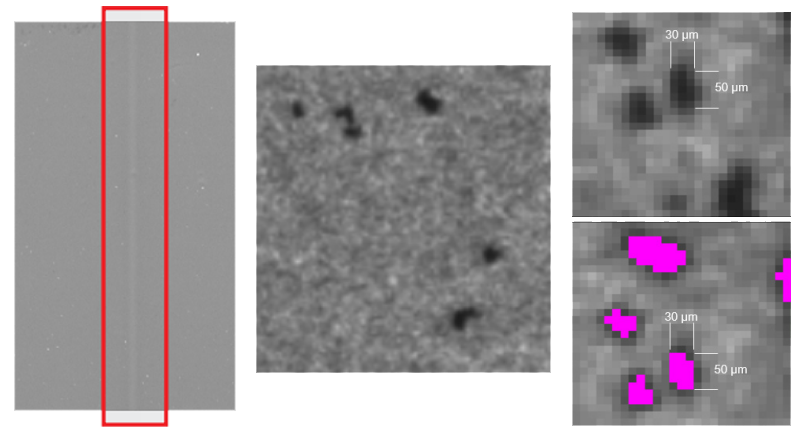

Typical defects during slot die coating:

Pinholes and divots

Pinholes and divots

Formed by air bubbles in the slurry popping during coating, these can cause localized over-charging of the cathode.

Agglomerates and blisters

Caused by improper mixing, these lead to non-homogenous conduction and binding, which can cause localized impedance rise and capacity loss.

Non-uniform coating

Strips, holes, folds, and other defects are formed when there is an obstruction on the coater, and can cause an uncoated line or localized over-charging.

Click here to contact us and discover solutions to meet your surface inspection challenges.